Product No:HY-6 series HY-E series

Brand:HONG YE JIE

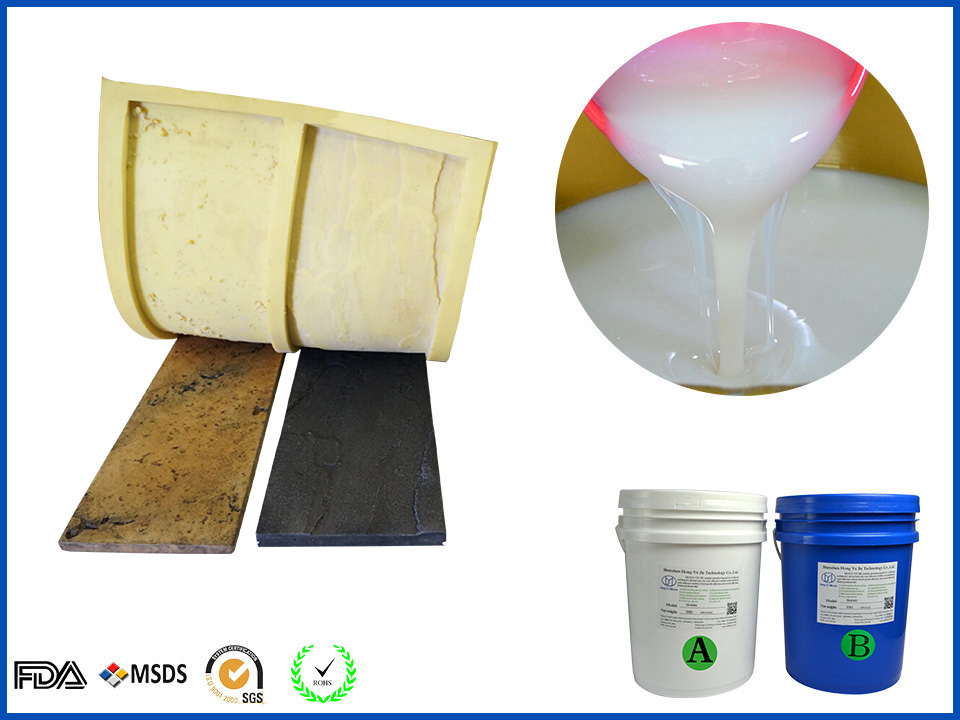

Product Usage:RTV silicone for stone molds can be used in the field of construction applications. Because the vulcanizing reactions of addition cure silicone is fundamentally different from tin cure silicone's, it has some characteristics that the condensation cure type do not have, such as adjustable curing rate, being completely environmentally friendly and so on. Therefore, our platinum cure silicone is particularly applicable for large stones molds, artificial stone molds, plaster and other architecture elements replication. The following is some detailed data about the performance of this model.

DESCRIPTION

RTV silicone for stone molds is very suitable for making silicone rubber stone molds. It is featured with extremely low shrinkage, good fluidity and resistance to many kinds of chemicals.This material do not release any by-product with low molecular weight during its curing process, and it's cured from top to bottom and from the inside to outside simultaneously, namely, deep curing. The E-sereise platinum cured silicone will not have the problem of degradation, sticky mold surface caused by the existence of by-product of small molecules under certain conditions, (such as closed environment, high temperature). Known from our customer's feedback, it is very convenient to make cement molds, and it is a high-quality silicone for construction industries. Further more, it can be applied to make multiple piece mold for products with complex design.

APPLICATIONS

RTV silicone for stone molds can be used in the field of construction applications. Because the vulcanizing reactions of addition cure silicone is fundamentally different from tin cure silicone's, it has some characteristics that the condensation cure type do not have, such as adjustable curing rate, being completely environmentally friendly and so on. Therefore, our platinum cure silicone is particularly applicable for large stones molds, artificial stone molds, plaster and other architecture elements replication. The following is some detailed data about the performance of this model.

MAIN FEATURES

RTV silicone is also featured with low shrinkage and nearly nil viscosity, good fluidity.Without releasing any by-product with low molecular weight, and it's cured from top to bottom, from the inside to outside simultaneously. It is suitable for the products with medium size or big size.

OPERATION INSTRUCTIONS

Step 1: prepare the original molds Prepare an perfect original mold and clean it totally before operation .

*Notes:Make sure your original molds and operation tool cleaned up totally to avoide uncure problem .

Step 2: Take 100 G part A and 100 G part B (Or 100 G part A and 10 G part B) and mix them evenly.

*Notes: Addition cure mold making silicon rubber is two part flowing liquid , Pls follow the step strictly: 1.Weigh the two part exactly by electronic weight.. If any part not in exactly weight , it may cause changing of hardness , or even cause uncure problem. 2.Mix part A and part B evenly. Otherwise the silicon rubber will be partly solidified and this will give birth to difficulties in your final operation. What’s more, the finished molds will meet a short life. All of these will cause a waste of silicon rubber.

Step 3: Vacuum pumping Without exception, this step takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step 4: Pouring casting or Brush operation

*Notes:1. For simple pattern products we suggest use pouring operation way , which will be very easy to operate and demould. Pourable silicone require light viscosity which will be easy to flow smoothly and easy to de-air . 2.For delicate pattern products we suggest use brushing operation way , which can copy the pattern exactly . Brushable silicone require high viscosity which won’t be easy to flow away and easy to brush . 3. We sugges to set the silicone mold for another 12 hours after demould before put into large production .

WARM TIPS

1.As addition cure silicone is a kind of platinum cure system ,which will be easy to cause uncure problem ,so Kindly follow the tips below :

*Do not mix with liuqid condensation silicone rubber or even the tool which used for condensation silicone

*Do not mix with organic matter which contains N, S, P organics and ionic compound like Sn, As,Hg, Ph,

*Do not add any pigment or powder into the addition cure silicone rubber without any testing to prevent uncure problem

PACKAGE

20KG/drum vacuum packing for part A + 20KG/drum vacuum packing for part B

200KG/drum packing for part A +200KG/drum packing for part B

SHELF LIFE

Twelve(12) months when stored under dry and cool place by original package under 25℃

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号