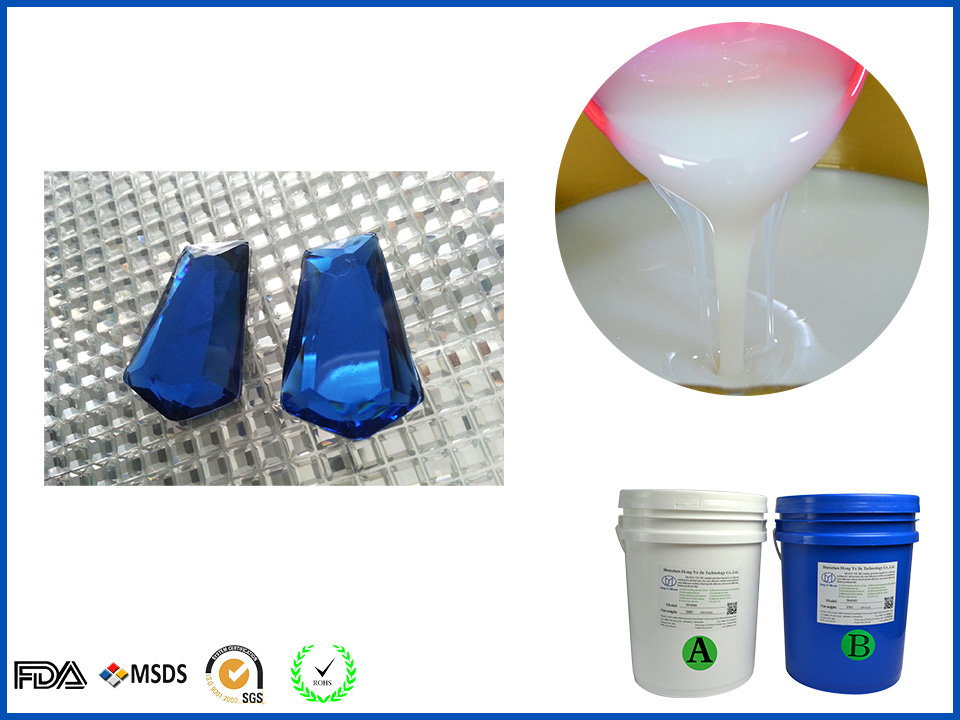

HEAT CURING SILICONE FOR INJECTION MOLDING DESCRIPTION

Heat curing silicone for injection molding is a two-component liquid silicone rubber with good dimensional stability, and good mold release, heat up to over 250°C, it is widely used in rapid prototyping gems mold.

HEAT CURING SILICONE FOR INJECTION MOLDING APPLICATION

Heat curing silicone for injection molding is mainly used for rapid prototyping gems molds,Resin diamond and etc.

RTV SILICONE FOR INJECTION MOLD CHARACTERISTICS

*An exceptional fluidity and good operability, easy to demold

*Good tensile strength and tear strength

*Good flexibility

*Outstanding bubble releasing

*Good duplication times

HEAT CURING SILICONE FOR INJECTION MOLDING PACKAGE

1, the product based with 20KG / drum packaging, the curing agent used 2KG / iron kettle Packaging

2, the product is non-dangerous goods, should be sealed and placed in a cool place, to prevent rain, sunlight exposure.

3, the product storage period of six months. If the viscosity increases during storage, under shear stress (mixing) can restore their mobility. It is recommended to use the first plastic material in the container with stirring, then add hardener mix. Extended retest is still using.

4, during the operation should avoid contact condensation silicone rubber curing agent. Vulcanized rubber material is not likely to cause there amines, sulfur, phosphorus-based

Copyright All Rights Reserved © SHENZHEN HONG YE JIE TECHNOLOGY Co.,Ltd 粤ICP备17107859号